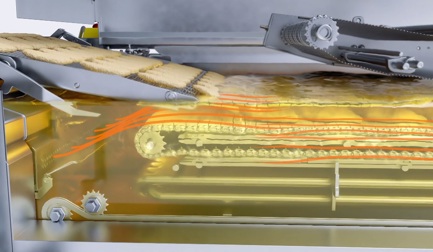

Technological advancements haven’t altered the core defeathering process

Plucking has hardly changed in decades

VC-i - The world's first intelligent vent cutter

Extensive performance monitoring with PUPIL AI technology

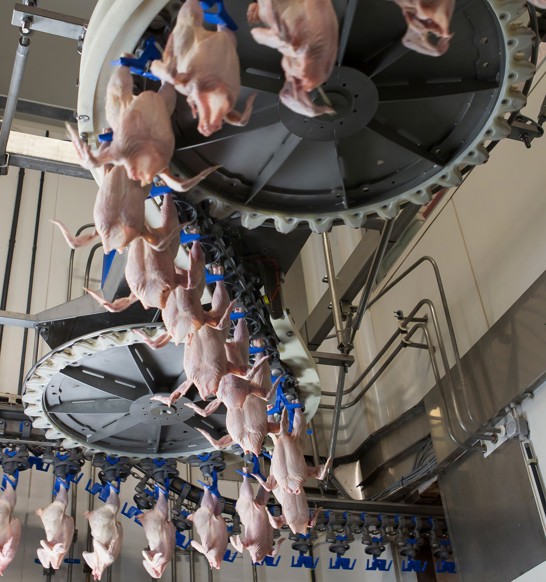

Setting benchmarks in the poultry processing industry

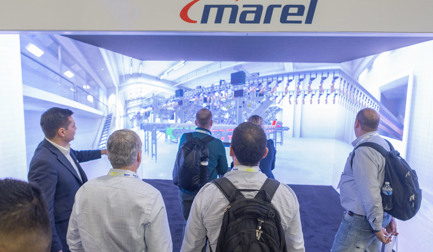

In close co-operation with our customers, we create innovative solutions for the poultry processing industry, driving excellence in performance, food safety and sustainability.

Download our industry brochure to get acquainted with our solutions and the passion we serve our industry with.

Choose your species:

Marel Food Processing Software

Marel Software enables food processors to collect and utilize data effectively, improving processing results and ensuring full traceability throughout the production process.

Service

To support our customers with the optimum service solutions, we focus on tailoring service partnerships to our customers’ specific requirements. Each service solution is designed as a partnership between our local service specialists and customers, to ensure it addresses specific needs.

At Marel, we envision a world where food is produced safely, sustainably and affordably. These goals are only achievable through close collaboration with our customers and partners around the world.

Our extensive global sales and service network spans 30 countries and six continents, so expert help is close at hand wherever you are. We believe in global knowledge and local solutions.

Highlight

Given the environmental requirements and the scarcity of water in some parts of the world, treatment of wastewater has become a very important aspect in the poultry industry.

Being a full-line supplier, Marel is able to supply made-to-measure water treatment solutions. These cost-effective and energy efficient systems solve many complex challenges posed by wastewater disposal.