At all times, the customer will hold the keys to the cloud.

Birgitta Strange

Marel Software Product Manager

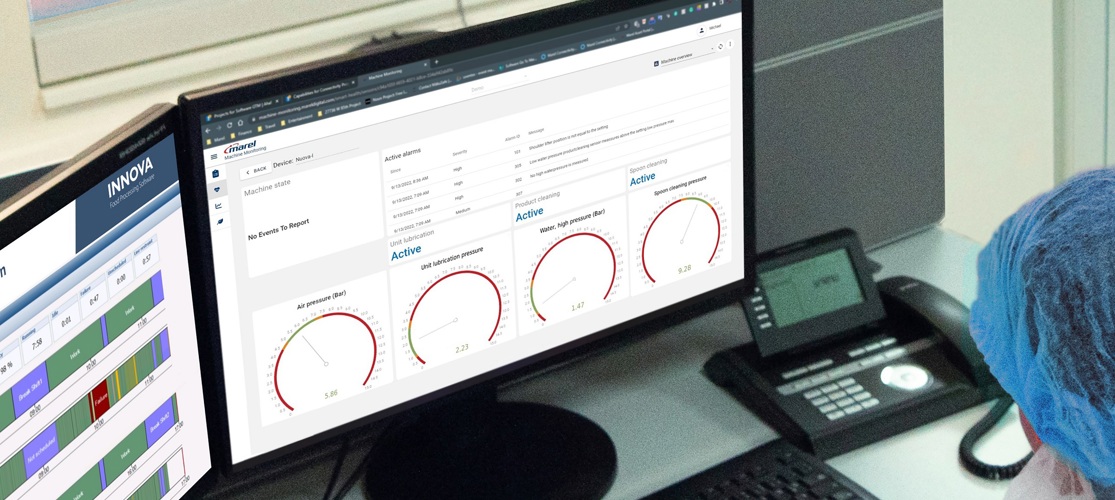

Poultry processing is becoming more and more digitalized. But what’s in it for the processor? Marel’s SmartBase machine software is a perfect example of digital connectivity that benefits the user. The data insight into the machine’s health gives processors a better understanding of their machines and processes in the factory. It empowers them to become more self-supportive and keep machine uptime close to 100%. SmartBase is already available on the SensorX and Nuova-i, soon to be followed by Spectra and MOS Oven.

Today, data is often locked in different machines and systems, preventing it from being easily accessible and usable for processors to make informed decisions. SmartBase unlocks data, providing web-portal access to real-time machine health and performance data. It is Marel’s initial step toward clouddriven solutions.

Birgitta Strange, Marel Software Product Manager, says, “SmartBase is the new digital standard for all Marel machines. It’s an integrated feature with currently no extra costs and zero installation time. Once you connect it, it organizes, sorts, and presents your machine data into a constructive form that immediately enables actionable insights. You can get insight into current and recent machine health and production data such as temperature, current, pressure, throughput, weight and alarms of the most critical components of the machine.

Michael Parrish, Marel Software Manager, says, “SmartBase gives our customers easy access to the technical health information of their machines. SmartBase can help them understand better how the machine performs and what the critical components are doing. Customers can have key data to become more self-supportive and increase machine uptime.” Helga Kristín Jóhannsdóttir, Marel SensorX Product Manager, adds, “Integrated SmartBase technology accumulates, organizes, and analyzes the data inside the machine that is now accessible not only on the HMI but also via an internet connection. Lots of this data was not visible to our customers before, which gives processors the ability to make betterinformed decisions.

At all times, the customer will hold the keys to the cloud.

Birgitta Strange

Marel Software Product Manager

“A cloud infrastructure allows customers to receive, store, analyze, and share data with greater flexibility and accessibility than traditional on-premises alternatives. Interconnected machines and processes on the processing floor benefit from quickly uploading and storing large volumes of data that can be analyzed to provide feedback and make data-driven decisions near real-time.” Helga Kristín Jóhannsdóttir adds, “When the data is locked locally on the machine, you don’t have the same opportunity to make quick, informed decisions that cloud-based solutions offer. The pandemic was a prime example of the benefit of cloud-based solutions because when nobody is allowed to be on the production floor, the remote accessibility of this critical data still allows to ensure optimum performance.

Birgitta Strange answers, “To connect a machine to the cloud, Marel needs the customer’s signed authorization. Both parties must agree to the data principles and security practices, so we manage security together. In the Microsoft Azure-based Marel Cloud, the customer’s identifiable information is safeguarded on the customer’s private database, explicitly owned and controlled by the customer. Marel will only access this information with explicit approval of the customer when service is needed. Multi-factor authentication is utilized for access to the databases as well, while a dedicated Marel security operations team is appointed for monitoring and responding to any suspicious activities. Data security and customer trust are Marel’s top priorities. The so-called digital ‘smart factories’ are securely locked and accessed only by those allowed inside. At all times, the customer will hold the keys to the cloud.”

SmartBase can help poultry processors understand better how the machine performs.

Michael Parrish

Marel Software Manager

Birgitta Strange replies, “Marel has a team of specialists available to guide the cloud-based solutions. They work with customer’s IT departments right from the start, ensuring that all questions are answered and addressing concerns or risks.” Michael Parrish adds, “Cloud-based solutions are new in our industry, and as anything new, there are understandable questions and concerns. We take the time to explain that we have built our solutions on highly secured data centers provided by Microsoft while ensuring that all communication between a customer’s factory and the Marel Digital solution is always authenticated, authorized, and encrypted. One day, this will just become a normal conversation: besides water, air and electricity, a plant needs a network.”

News

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.