Information

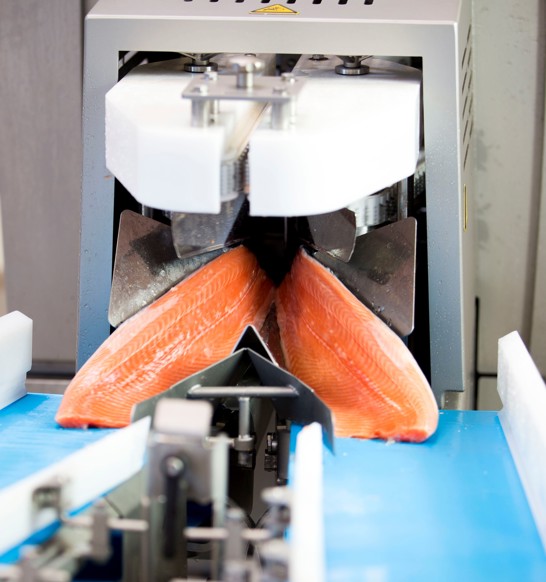

Automatic size adjustment

The machine uses an automatic size adjustment feature to fit fish from 1.5-8 kg, resulting in higher throughput, quality, and yield on every fish.

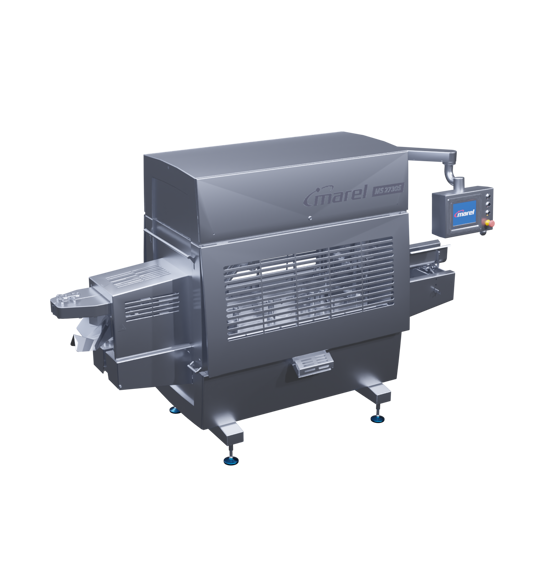

User-friendly touchscreen

The multilingual touchscreen helps ensure maximum safety for the operator, who can easily make adjustments and change programs.

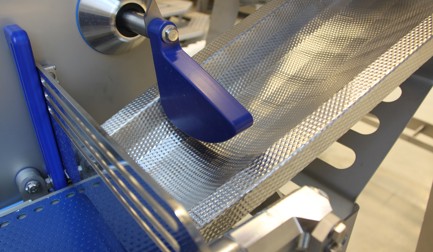

Automatic back and belly trimming

The optional trimming tools automatically adjust to the size of each fish, minimizing the need for manual trimming after filleting.