Information

We provide whips and brushes for use in carcass cleaning machines. They are available with a plug connection or a click-on system. The click-on system in particular has some additional advantages.

Thanks to their sophisticated shape and click-assembly method, our click whip and click brush are an innovation in the field of cleaning pigs. Compared to the traditional whip, our click whip guarantees optimum cleaning results with minimum water use and a significant reduction in operational costs, thanks to its specially developed shape.

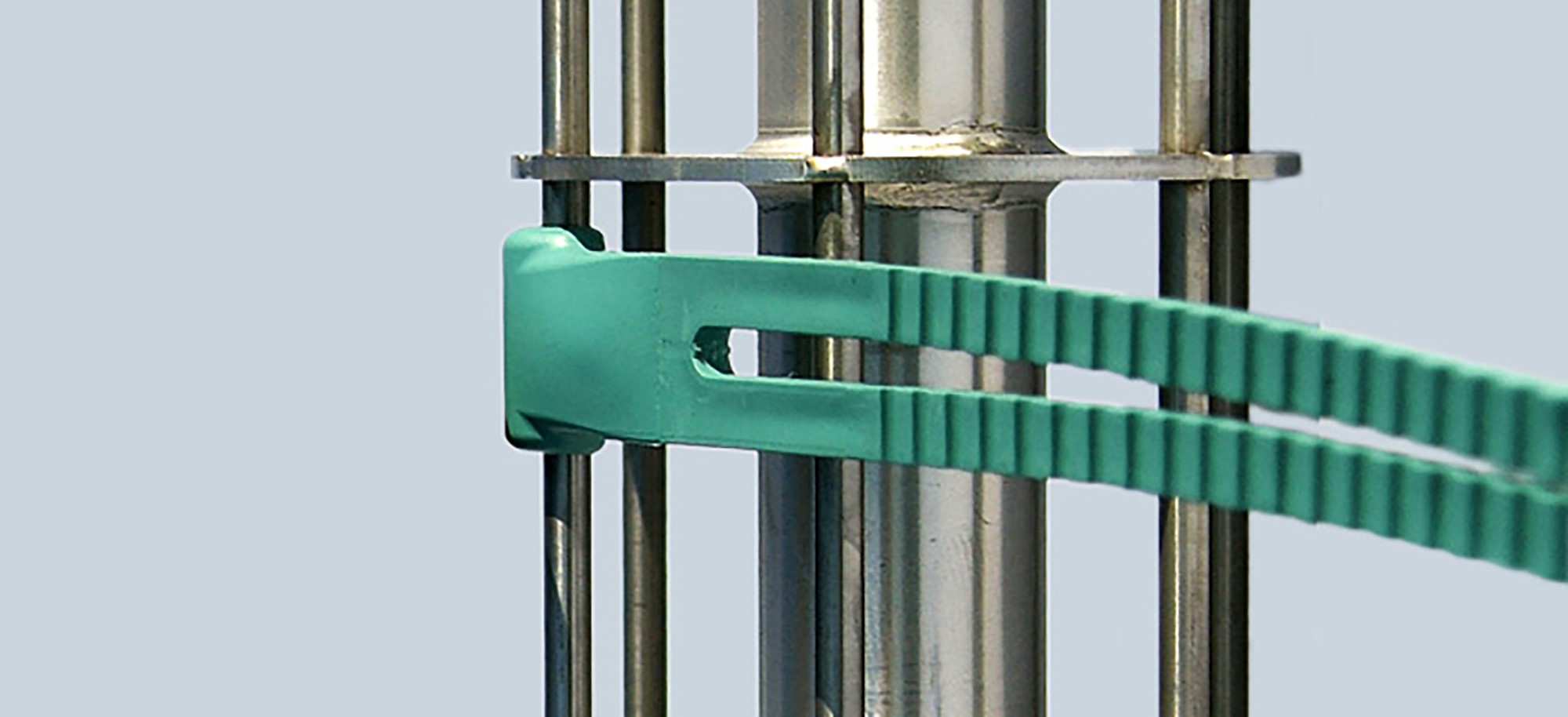

Because the whips can be clicked easily onto the cylinders of the cleaning machine, parts of the machine do not need to be disassembled to replace the whips. A major advantage is that they can also be replaced individually.

Through extensive research and feedback from a number of valued customers, we have supplemented the product portfolio with a number of new click whips that significantly increase the effectiveness of the dehairing process. It is a generally known fact that in the ‘winter hair season’ it is even more difficult to clean carcasses in troublesome areas.

We have designed whips with a higher degree of hardness (+10%), which increases the force exerted on the scalp.

In addition, we have also produced click whips with greater reach (additional 50 mm) that can reach difficult areas, for example positions on the neck and in the groin area.

By installing your own special mix of whips in the cleaning machine, it becomes possible to achieve an optimal and customer-specific dehairing result.

Both new click whips can be mixed on a shaft with the regular click mechanism in order to optimise the dehairing result.

All whip types are suitable for use with existing cylinders or can be acquired in combination with Marel stainless steel cylinders .