“FATscan is designed to help poultry processors deliver a consistent and uniform product.”

FATscan is designed to help poultry processors deliver a uniform high quality product, while reducing their costs and time. Until now, off-line analysis methods involved a lot of manual labor, human errors, inconsistent product quality and failing traceability.

Higher profits

Now, with FATscan, poultry processors have more control of their process, products and suppliers. The in-line system can supply a consistent poultry meat product with minimum lean giveaway by controlling the process in real-time. Thanks to the maximized use of raw materials, this technology results in improved productivity and profitability. FATscan reduces the need for manual labor such as rework and therefore generates fewer human errors. It also saves cost and time while offering easier traceability.

How does it work?

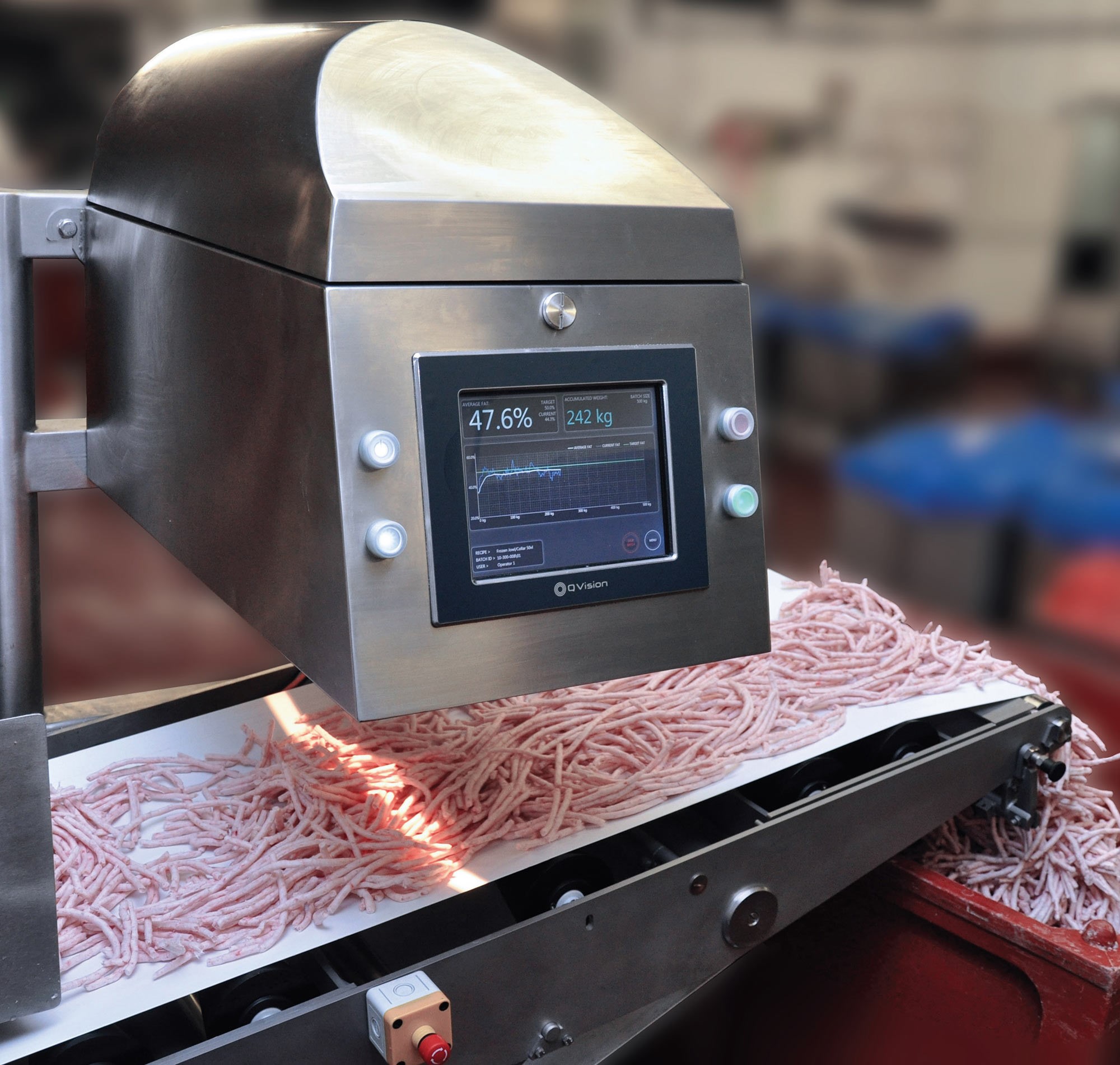

FATScan accurately measures and displays the chemical lean (CL) content –the valuable component of meat– in meat trimmings, minced or diced meat. It applies a unique spectroscopy technology which emits visible and near infrared (Vis/NIR) light to penetrate deep into the meat. Sensors then capture the returned transflected light with information about the absorption behavior to make a fat/lean analysis. Based on this analysis, the poultry processor can adjust the mix of meat components to ensure the consistent fat percentage of the end product. In this way, the precise control ensures superior quality and consistency of the final product, either fresh or frozen.