Cost-effective intralogistic systems are needed in most businesses today as part of the move towards automation.

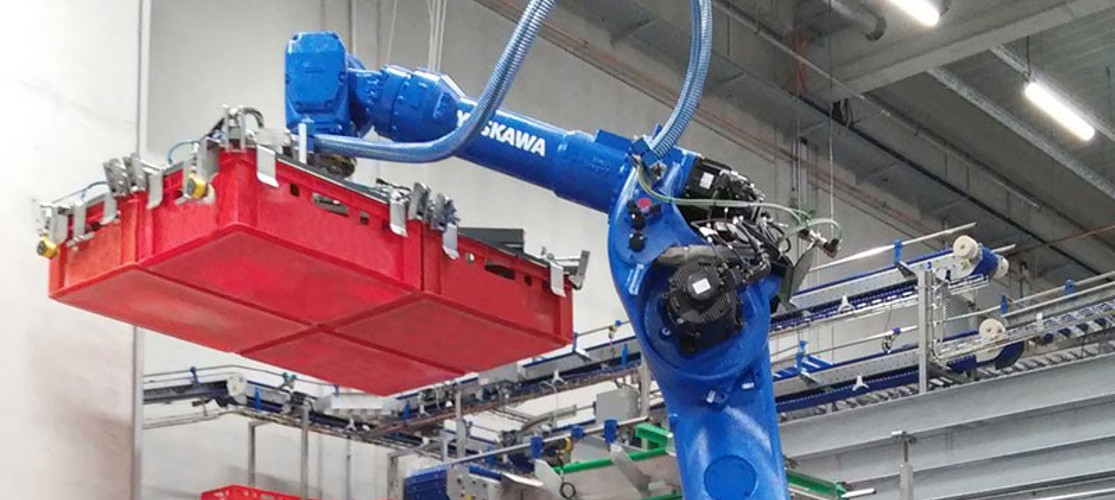

The intralogistics systems from Marel are modular making them easy to fit into already existing plants. The systems range from small conveying systems to large integrated turnkey projects.

Will Gubbels, Business Unit Manager at Marel Food Logistic Systems explains, "Our primary focus is on the red meat processing industry – where automation is key and where tremendous amounts of raw material and end products are conveyed, moved, buffered and stored at several stages of the value chain."

The intralogistics systems interface seamlessly with the Innova Food Processing Software to ensure full control of the products throughout the complete processing, storage and distribution process.

- Conveying systems (belt conveyors, roller conveyors and accumulation conveyors)

- Material handling equipment (sorters, de-stackers, palletizers and de-palletizers, lifts and robots)

- Automatic storage and retrieval systems (automatic high-speed cranes, and racking) including warehouse management systems

- Order picking and labeling systems

- Empty crate buffer systems

- Crate washing systems

- Software solutions