Information

A schnitzel is thinned meat, coated with flour, beaten eggs and bread crumbs, and then fried. Originating in Austria, it is popular in all parts of the world. Marel's Schnitzel Line is able to produce high-quality, perfectly coated schnitzels which respond to the requirements of consumers around the globe.

Whole muscle or formed

Schnitzels may be created from whole muscle breast fillet meat. In this case, they need to be sliced in the TSM Profiler or SmartSplitter to present a consistent thickness and weight to the Schnitzel convenience line. It is also possible to create formed schnitzels from meat mass with a RevoPortioner. The meat mass has to be prepared by Marel's Meat Preparation solutions to achieve the right consistency and viscosity for RevoPortioner to form it into consistent products with uniform shape and weight.

The first step of coating will be done in the Active Flour Applicator. A layer of flour, also called pre-dust, is applied in this stage. The fine layer of flour serves as an adhesive. It also supports the juiciness of product and adds yield. Now the schnitzel is ready for the wet coating. The Active Batter Applicator applies an even layer of batter on the top and bottom side, for the dry coating to stick to the product later on.

Crumb management

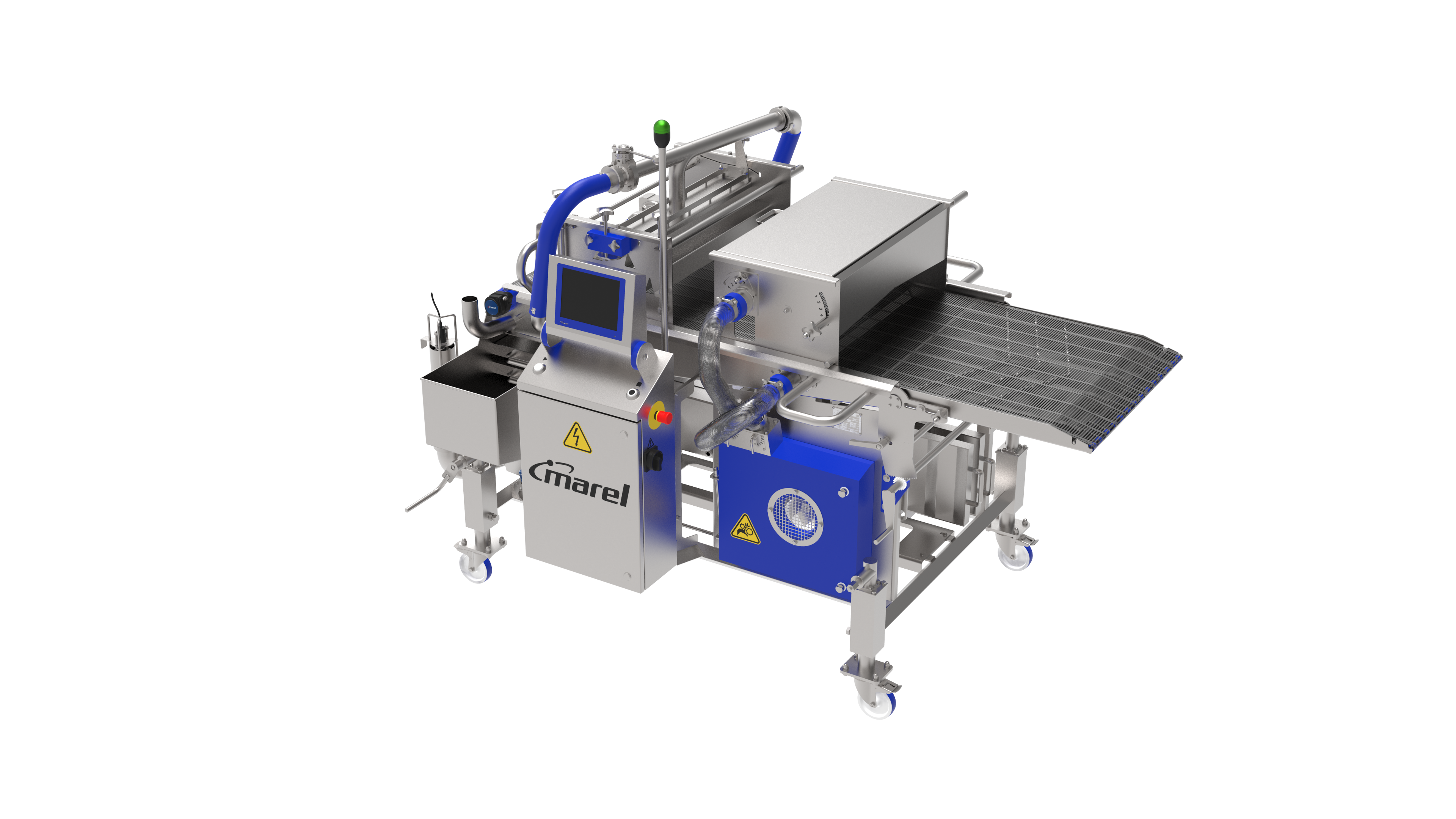

The final step in the coating process is to apply crumb. Depending on the customer's wish, the schnitzels can be covered by fine breadcrumbs or coarse product such as cornflakes, depending on end product requirements. Crumb is applied gently, so large pieces remain intact. Spreading of the crumb on top and bottom is very important, which is why RevoCrumb works with an innovative crumb management system to control the distribution of larger and smaller pieces on the schnitzel.

Now the schnitzels are ready to be par-fried, so they only stay in the GoldFryer for a limited amount of time. This is done to fixate the coating around the products, and to maintain the appearance. After this, the products are not safe to eat yet, so they enter the oven until they reach their desired core temperature, while their juiciness remains optimal.