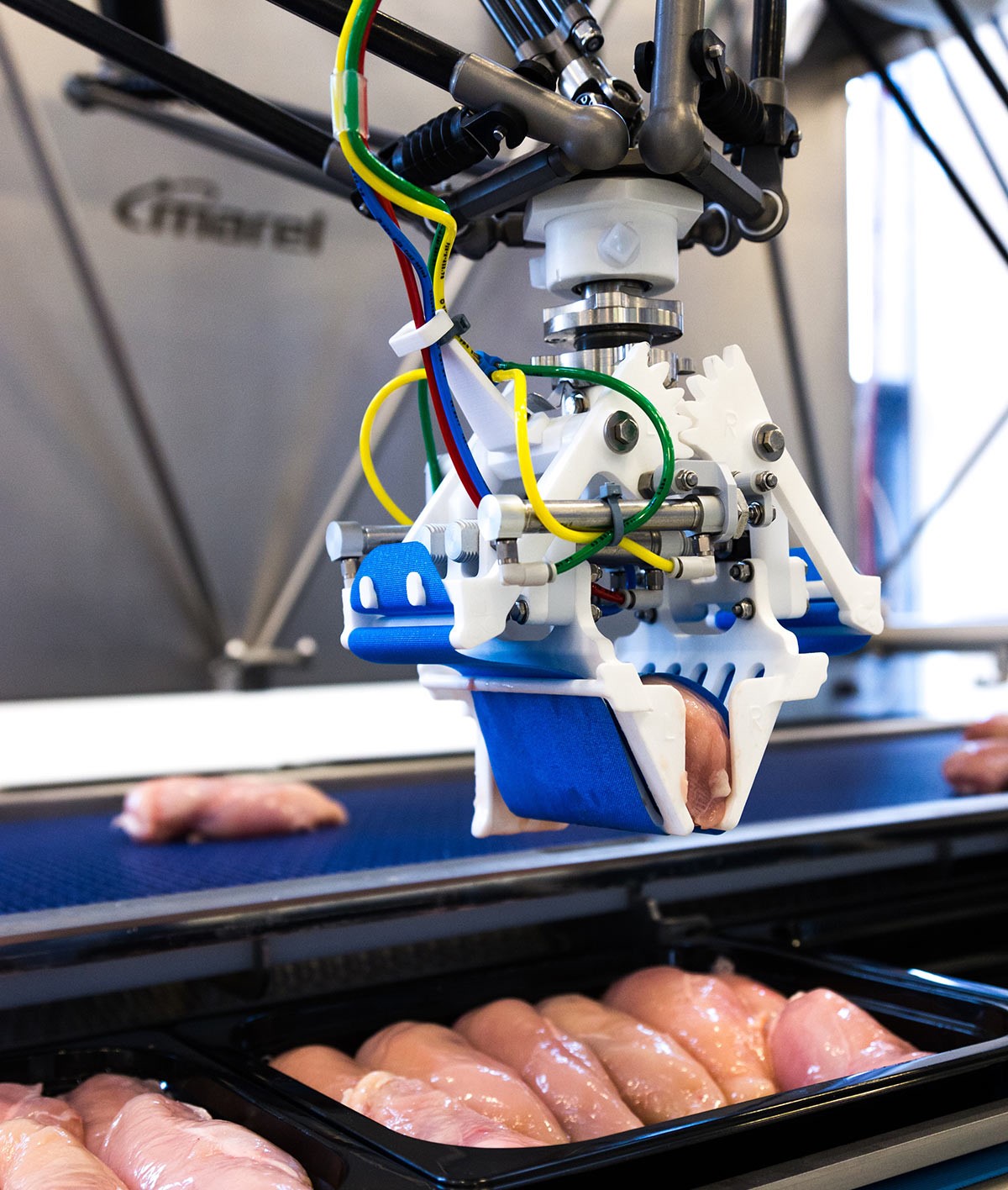

The new grippers save labor and have been designed for easy use. They are easy to clean and changing them is a quick job with no tools necessary. All grippers connect to the base in the same way and have a quick change adaptor. Changing grippers to handle a different product can be done simply by hand in less than a minute.

Tray styling

With supermarkets’ insistence on attractive presentations, tray styling is a hot topic among poultry processors. The new grippers are the perfect answer for fillets, drumsticks and whole legs.

Søren Raahauge, Marel Product Manager Robotic explains; “Improvements in styling performance also save labor, as there is much less need for trimming or restyling afterwards. This is a welcome benefit as finding qualified staff is becoming a bigger challenge for poultry processors everywhere.”

Don't drop

The RoboBatcher’s vision system detects the orientation of every product on the belt, passing this information to the gripper. This allows for it to adjust its angle, always picking up the product in the same way. The new grippers do not “drop” products into the tray, as bounce would cause a loss of control over how products land.

Instead, the gripper moves to the bottom of the tray to release product at exactly the right spot. The jaws of the gripper open no more than necessary, which is particularly important for the last product in a tray.

Søren Raahauge concludes, “We will continue to focus on improving the performance of our grippers. By making increasing use of robotics, new grippers will be able to handle even more poultry parts”.

Fillet gripper

In tray packing situations, the tail (end) of a breast fillet may protrude over the edge, making sealing impossible. The new RoboBatcher fillet gripper has a tail bending device, which pushes tails down when picking up fillet. The gripper then descends into the tray. Its jaws open and shut without any pressure; tensioning of the belt between them positions the fillet.

Grease on the tray and protruding tails no longer compromise sealing performance, which results in unequalled automatic styling.