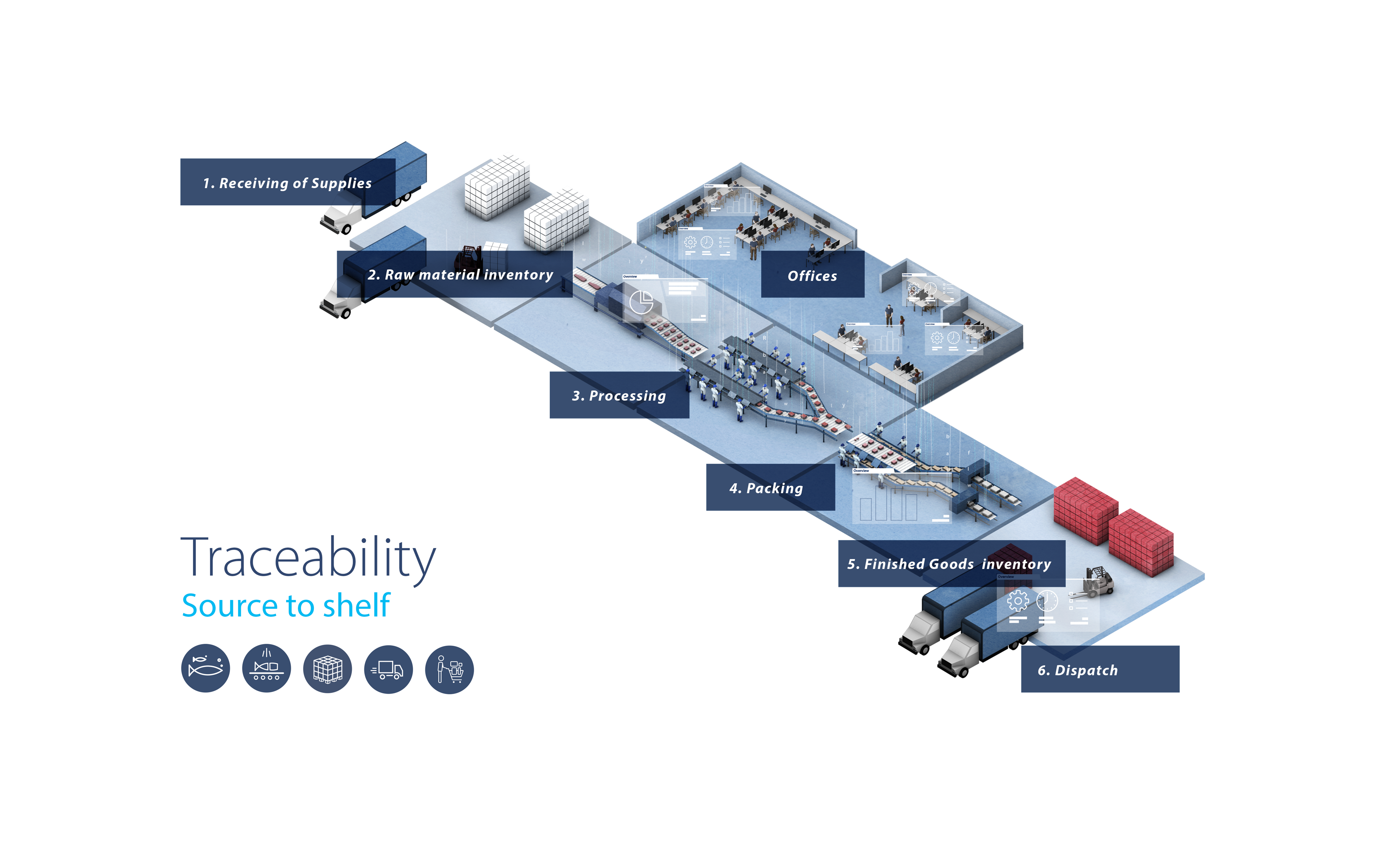

Innova is a powerful and comprehensive software that collects and collates data, allowing food processors to improve performance and enhance productivity. From product delivery to final output, Innova streamlines processes, minimizes unplanned downtime, and will enable processors to hit ambitious targets.

Managers have full control of the production process. Information can be displayed in reports and external systems to allow for comprehensive cost analysis and production planning. This allows managers to increase throughput, reduce giveaway, better use labor and raw materials while managing full traceability of the final goods.