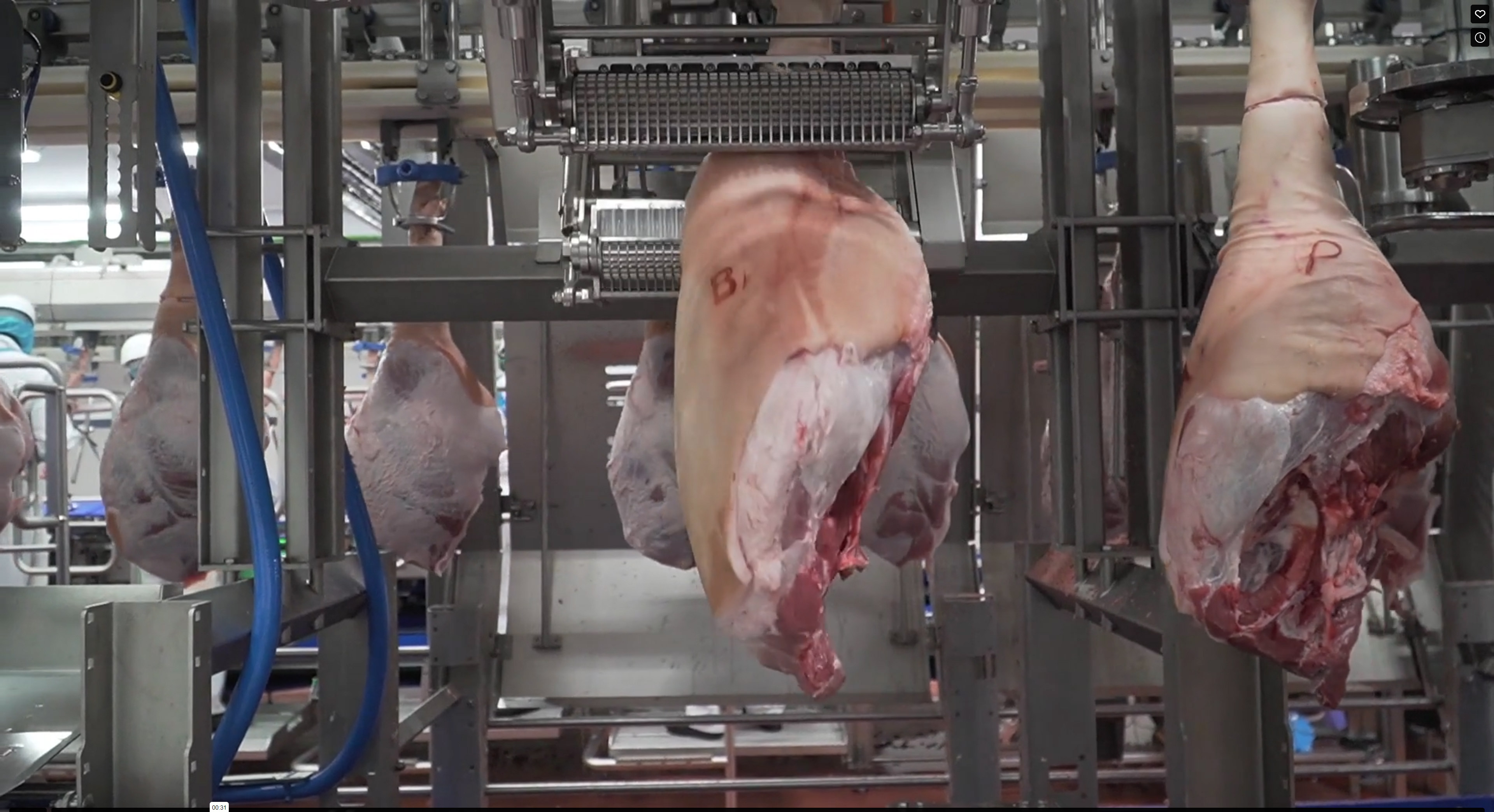

As a full-line supplier, our state-of-the-art meat processing equipment, systems and software span the entire production value chain, from the reception of live animals to the dispatch of finished products.

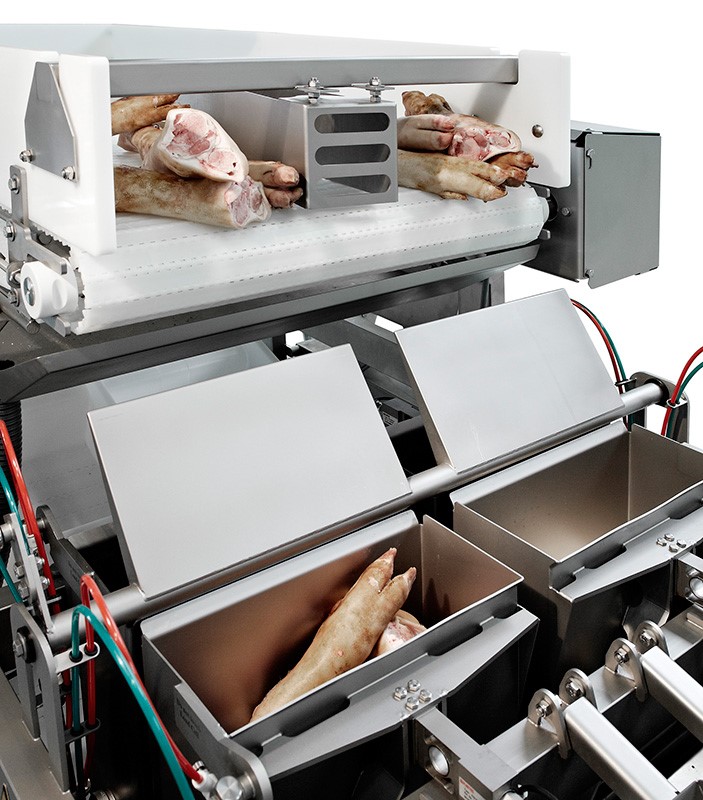

We work with all processes in the slaughter, cutting and further processing hall as well as case ready and food service packing, all of which can be integrated with Innova software.

Whatever your location, business size or objectives we can help you to operate at peak productivity and enhance the overall quality and value of meat products