Full process control

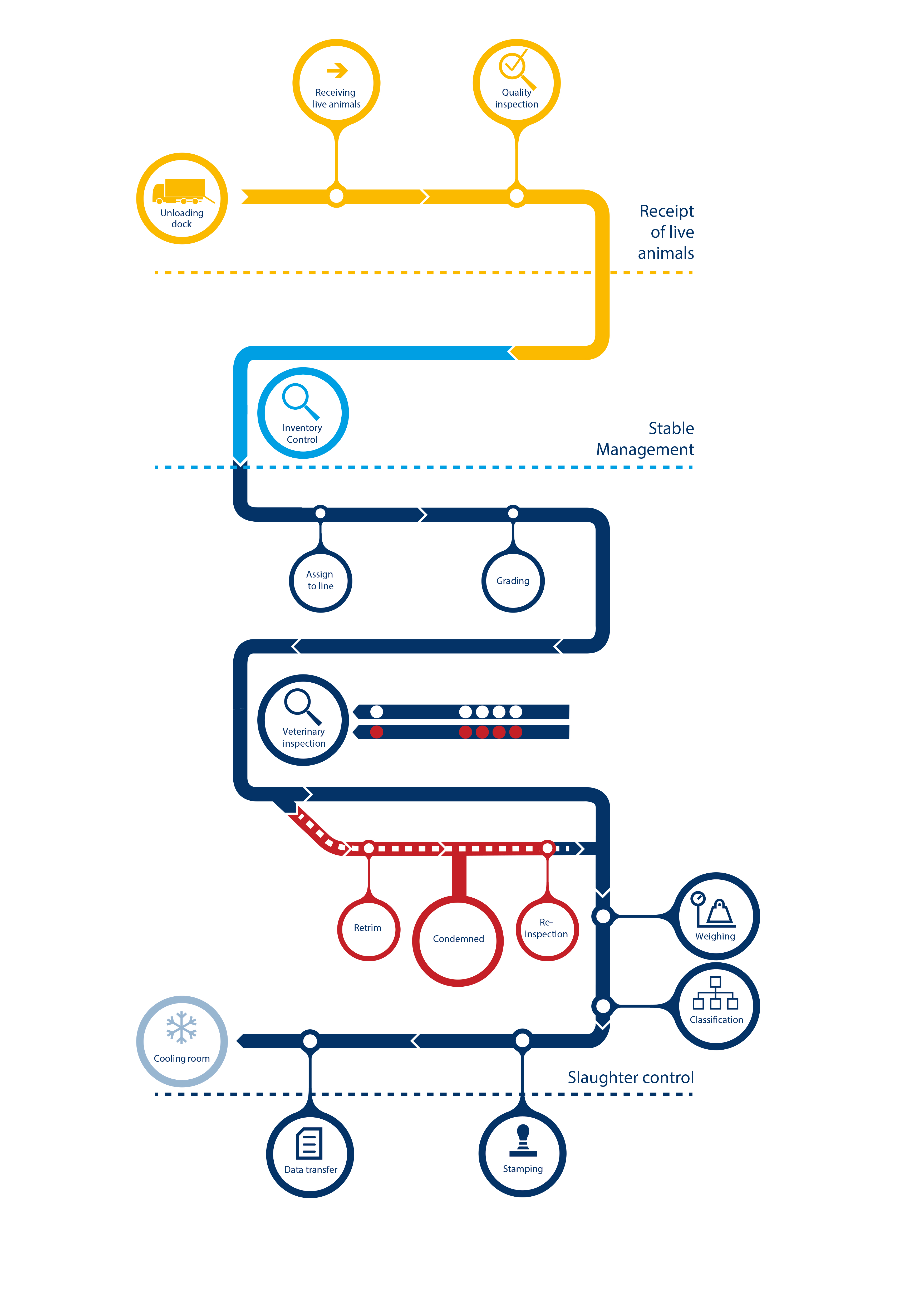

From the moment live animals are received, the Innova Primary Pork Processing Software ensures they are registered against a purchase order and details from the initial inspection are captured. It is at this point that the traceability chain begins. Truck weighing and quality inspections are options that can also be added.

During stabling, the operator assigns animals to pens or lanes. The system then connects pens with the planned slaughter process. The information collected by the system not only provides a real-time, live-animal inventory but also improves animal well-being by registering both the filling rate of each pen and the total stable time.

After stabling, animals are taken through the slaughter process for stunning, killing and bleeding, scalding and dehairing to the clean slaughter line. From here, the system assigns animals to individual hooks and sequences them with a kill number. This ensures all data collected can be linked to individual carcasses throughout the slaughter process.

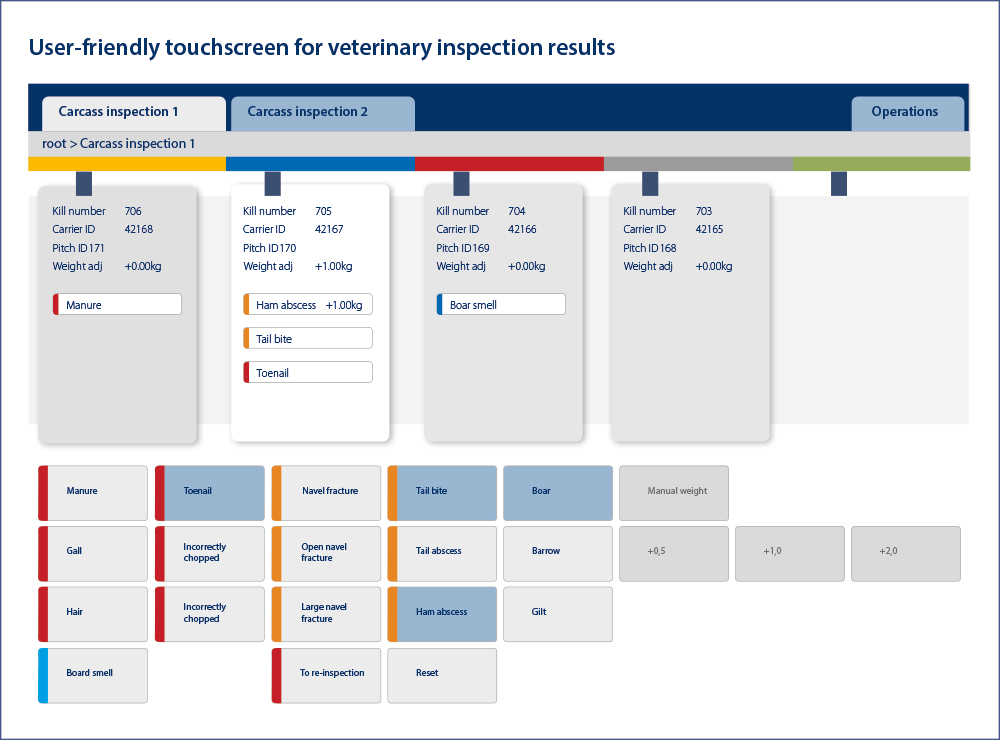

During the grading process, the fat-to-lean ratio is recorded for each carcass. After this, the veterinarian inspection records any defects and registers remarks concerning quality.

The system then uses this information to send a carcass, if required, to re-trim, re-inspection or to be condemned. At the same time, terminals provide important information to operators, such as where to trim a flawed carcass.

Carcass classification

Based on the data collected throughout the primary process the system can automatically give each carcass a sorting class using a classification matrix module. Carcasses with a particular class have similar characteristics allowing them to be stored together on specific rails in the chilling room, helping to achieve optimal order fulfillment.

Performance management

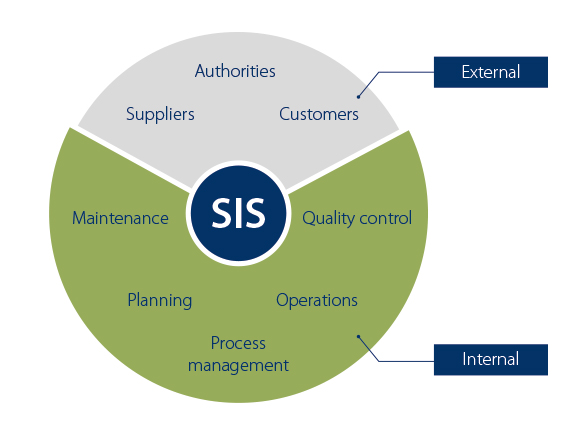

The data that the system captures and registers is used to create dashboards and reports, which give valuable insights into production and quality.

This information supports multiple functions across the organization and can help different stakeholders manage and improve the slaughter process in different ways. It also plays an important role in supplier evaluation.

Detailed planning

Using the data collected for each carcass, the system generates a precise overview of what is being processed. The level of detail gives the planning department a clear overview of what raw material is available for the next stage of processing. This allows them to ensure maximum value is obtained from different parts of the carcass and to accurately plan order fulfillment.