Information

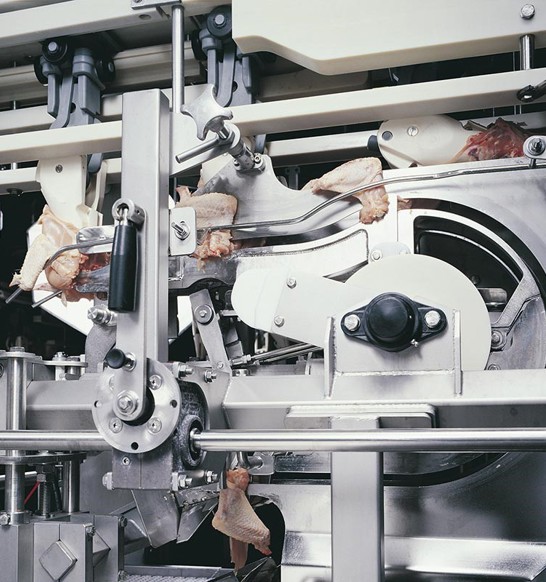

FHF FlexControl is a fully automated front half filleting system made up of processing modules installed along an overhead conveyor. The system produces a wide range of breast meat products (with and without back meat, with and without tenderloins) for retail and industrial customers.

Automated from start to end

From start to end of the FHF line, products and by-products are harvested automatically. No manual action is required, from neck cutting to tenderloin harvesting.

The FHF FlexControl deboning system is fed with front halves with wings or at least their inner joints left on. This allows eye meat to be harvested for maximized yield. The system will cut whole wings into individual wing joints. These are harvested separately. Apart from the fillet/wing harvesting module, FHF FlexControl features a tenderloin harvesting module, capable of harvesting remaining baby tender along with the tenderloin. Valuable by-products such as skin, crop fat and breast tendon meat are also harvested automatically.

High hourly capacity, unbeatably high yields and low manning levels set new standards in the kgs per man hour possible.

Monitoring and tracking

The implementation of PLC technology enhances the performance of the FHF modules, while also being user-friendlier. PLC control provides line monitoring and accurate tracking of the front halves through the modules, ensuring a consistent job done with correct timing and stable accuracy. This improves the reliability of the FHF FlexControl system and benefits uptime.

Touchscreen

The HMI touchscreen gives access to the PLC-driven, pneumatically activated modules of the FHF FlexControl system. Entering a recipe for the weight of the flock about to be processed is straightforward. The timing of the PLC-controlled actions in the deboning line will adjust accordingly. By clicking the appropriate flock weight on the touchscreen, the relevant FHF modules will automatically set themselves to the weight range.

FHF FlexControl is more robust and safe than ever. The latest techniques have been applied to benefit performance, yield, line efficiency and cost of ownership.

- Overhead conveyor based system - great layout flexibility

- Modular setup - can be extended

- Recipe controlled

- Seamless integration into downstream trimming, bone detection and further processing operations