Information

The ALPINE (Anatomic Leg Processor Innovative New Evolution) leg processor ensures simplified, proven performance across a broad weight range of products, up to US big birds. With user-friendly operation, robust design, and consistent optimal performance over an extended period, it delivers high-yield leg cuts with low complexity and minimal adjustments during production.

A consistent job

ALPINE is a state-of-the-art anatomic leg solution that excels in consistent performance, ensuring a high yield, product quality, and meat integrity. ALPINE maximizes leg meat harvesting and keeps the meat muscles intact with the white cap visible, typical for an anatomical cut, ensuring a consistently high yield performance.

Despite its compact size, ALPINE is robust and less sensitive to maintenance requirements, making maintenance simpler overall.

Easy control

ALPINE is equipped with an HMI touchscreen for entering the appropriate recipe, taking into account the weight, shape and size of the incoming flock. The mechanical settings will then follow these recipe instructions.

To keep an optimal consistent performance per flock with different product specifications, it is possible to optimize the settings manually.

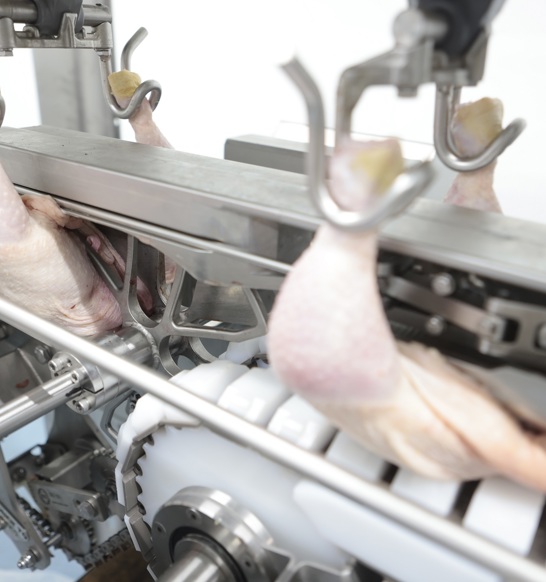

Legs stay in the shackle – Hip Dislocation Wheel

ALPINE employs a unique Hip Dislocation Wheel located in the middle, actively taking control of the hip tilting movement without exerting any forces on the leg and without taking legs out of the shackle. In this way, legs stay fully controlled in the shackle throughout the process, resulting in improved performance.

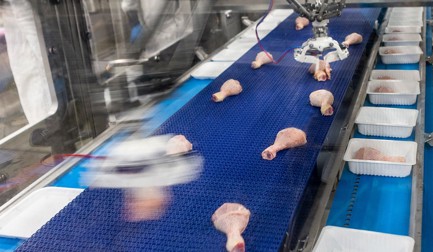

Back piece detection

In leg processing, back pieces need to be correctly separated to prevent faulty legs from advancing downstream, such as to the Thigh Fillet System. Once the ALPINE system has processed the leg, it detects whether the back piece has really been integrally separated, both for left and right legs. PDS software ensures that faulty legs are directed to a drop station for rework.

Saving labor

ALPINE saves labor because its operation demands little to no human intervention. Thanks to the low complexity, minimal adjustments are needed during production. Operating consistently throughout a flock or even a whole production day, its simplicity and low sensitivity to maintenance reduce dependence on skilled or non-skilled labor for the operating and servicing of the machine.

ALPINE also saves labor because of its high performance in preventing product drop-outs. With so many correctly processed legs, hardly any rework is needed.